The science behind PVC: a simple guide

PVC is a material widely used for all kinds of projects, but what is it that makes it so useful? Here we’ll give you a simple guide into what makes it work, and why it makes the perfect choice for curtains in a variety of uses.

The basics

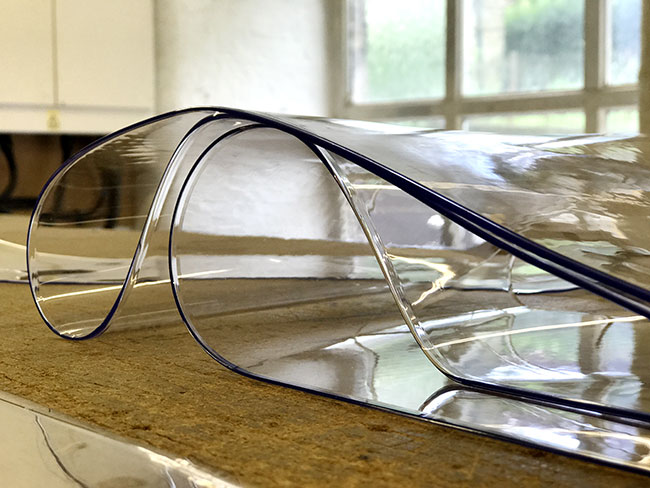

To give it its full name, Polyvinyl Chloride is a polymer which is used extremely widely across the globe. Industrial, technical, electrical, medical, and everyday applications are common. This is because of the properties that it holds: it is durable and long-lasting, can be made either rigid or flexible, and can be clear or coloured.

The first patent for the manufacturing process of PVC was registered in 1913 by a German inventor named Friedrich Klatte. Commercial production of the material began in 1933, and now it accounts for around 20% of all plastic which is manufactured. Only polyethlene claims a higher percentage.

Production

How is PVC manufactured? It starts with salt water, which goes through electrolysis to produce cholorine. This is combined with ethylene from oil, which forms a vinyl chloride monomer (VCM). When the VCM molecules are polymerised, this forms PVC resin. Once you incorporate the appropriate additives, it makes a customers PVC compound which can give you the specific characteristics you require.

These are the five steps of manufacture broken down in simple bites:

- Extract salt and hydrocarbon resources from water and oil

- Produce ethylene and chlorine from those resources

- Combine the two in order to create VCM

- Polymerise VCM to make PVC resin

- Blend PVC resin with other materials to produce the properties you want

Sustainability

There are obvious concerns about the use and manufacture of plastics, but the good news about PVC is that it takes less non-renewable fuel to make than any other type of commodity plastics. They are normally made from only oil, where PVC is also manufactured from salt. In some regions, PVC is also made without oil feedstock at all, using bio-derived hydrocardon feedstock instead.

Products of manufacture

When PVC is manufactured, there are a couple of products and by-products that are also created. These are chlorine and caustic soda – both of which are hugely useful in the world at large. Chlorine makes 85% of pharmaceuticals, as well as keeping swimming pools clean! Caustic soda is used in soap, paper, detergents and cleaners, in the food industry, in textiles, and so on.

Additives

The high versatility of PVC comes from the way different additives will produce different results. PVC can be produced in a plasticised form to be flexible, or unplasticised as PVC-U to be rigid. Heat stabilisers, lubricants, pigments, impact modifiers, flame retardants, UV stabilisers and so on can all be added.

These add, respectively: protection against heat or low temperatures, low friction, different colours, resistance to damage, resistance to fire, and protection from damage by the sun. PVC is in fact fire retardant as a base material because of the presence of chlorine, but it can be enhanced further.

Due to the use of additives, you may be surprised to find that the actual PVC content in some applications – such as floorboards – can be as low as 25% by mass.

Benefits and properties

These are the properties of PVC which result in it being so useful:

- Excellent electrical insulation (perfect for cables)

- High impact strength

- Consumes less primary energy during production than other plastics

- Insulation for windows and curtains

- Relatively small carbon footprint

- Lightweight

- Rated for extensive European food contact and medical use

There you have it – the science behind PVC, and what makes it such a great choice for so many uses!